Natural vs. Machine-Cut Porphyry:

Recognizing the Variation Porphyry is produced in two principal surface styles: natural cleft and machine-cut. While both types are derived from the same volcanic stone, their methods of extraction, formation, and finishing distinguish them. Natural cleft porphyry features a raw, organic surface that highlights the artistry of nature. Conversely, machine-cut porphyry delivers a sleek, uniform finish suited for specific design requirements.

Natural Cleft Porphyry – Formed by Nature, Preserved by Craft

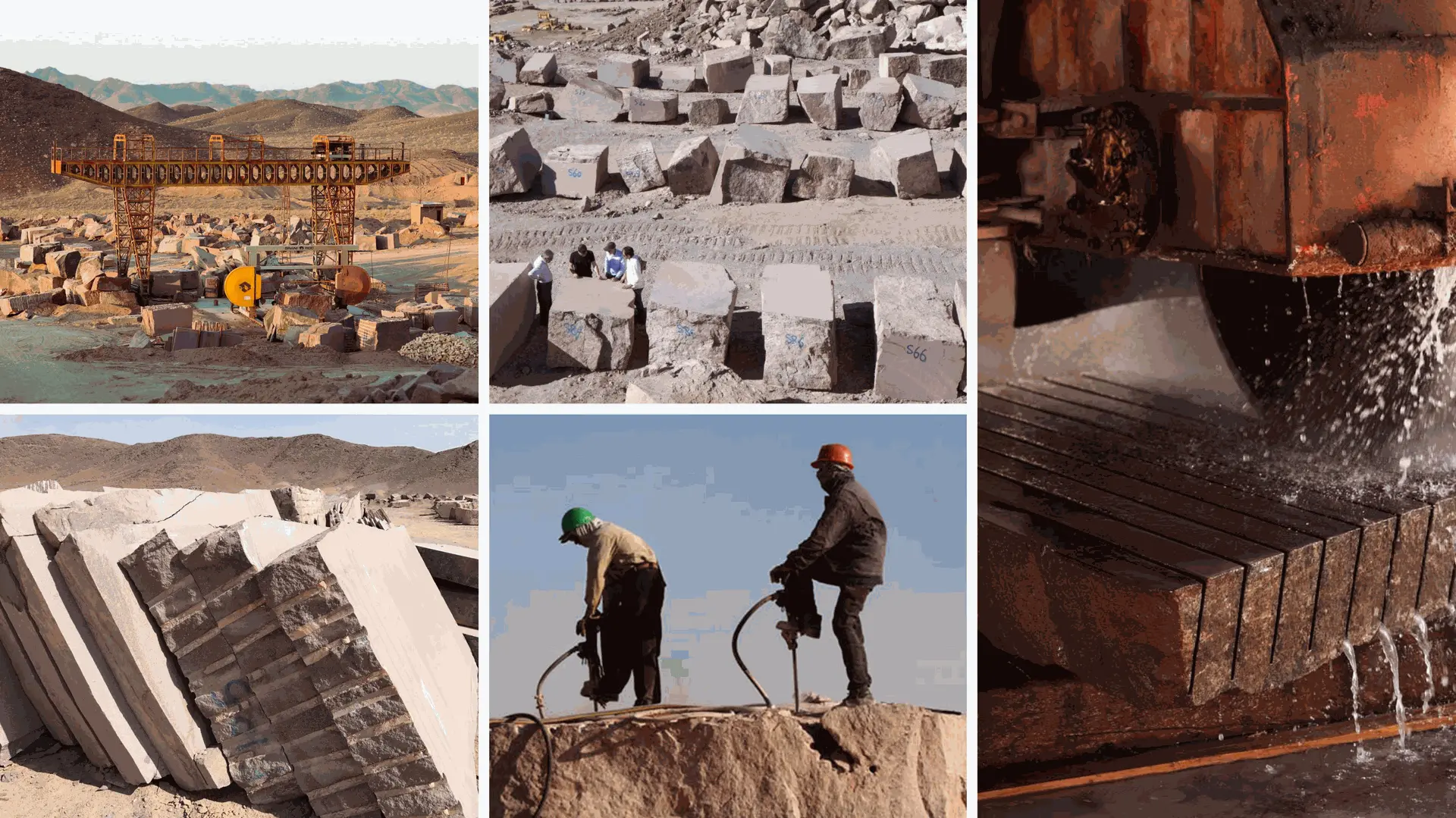

Natural cleft porphyry is more than just a surface; it embodies the legacy of countless years of volcanic activity and geological layering. This distinctive stone formation can be effortlessly split into sheets along its natural bedding planes, maintaining its authentic texture without the need for polishing or artificial enhancements. Once extracted, the slabs are categorized by their thickness and size, with the only processing being the division of the stone into architectural formats like cubes, tiles, and pavers tailored to specific project requirements. The outcome is a genuine, slip-resistant surface that showcases the raw beauty and durability of the mountain from which it originates. Its rich, earthy hues and naturally rugged texture make it perfect for outdoor hardscaping, public areas, and any endeavor that aims for a grounded, organic look. Each installation reflects the timeless irregularity of nature, infusing depth, character, and enduring value into architectural environments.

Machine-Cut Porphyry – Precision for Modern Needs

Machine-cut porphyry is created by precisely slicing and calibrating the stone to achieve a consistent thickness and size. Its polished surface and sharp edges make it ideal for modern designs and indoor settings where accuracy is essential. Although it has the same mineral makeup as natural cleft porphyry, its appearance is more uniform and less textured, providing a sleek, contemporary aesthetic. The machine processing enables quicker installation in modular layouts, but it does lose some of the natural allure present in its unprocessed version.